Plastic Sheet Extrusion Specialists

After many successful years manufacturing in the automotive industry, PRO-FORM has gained significant plastic extrusion expertise to create custom solutions for external customers. PRO-FORM have kept at the forefront of plastic manufacturing by continuously innovating and adding technical modifications to their sheet making process. Today PRO-FORM distribute quality sheet throughout New Zealand, Australia, and the world.

See below for more information on the technical capabilities of PRO-FORM’s plastic extrusion manufacturing.

Capabilities

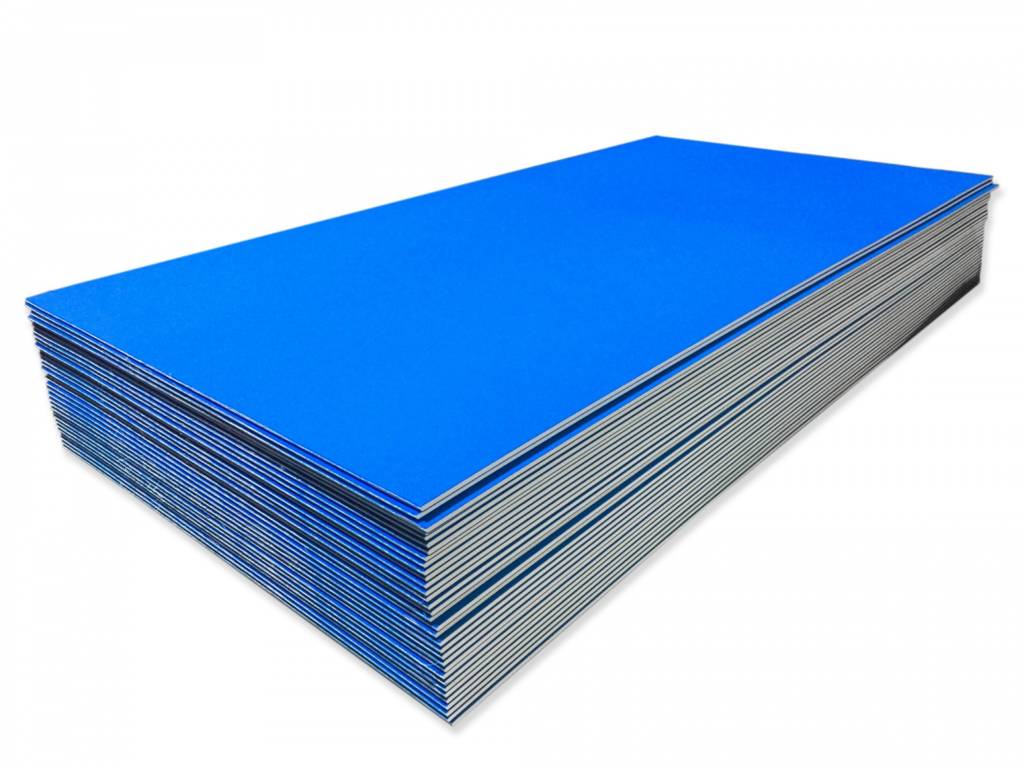

PRO-FORM have three large, multi-layer extrusion lines which all have slightly different capabilities. Between the three of these machines, PRO-FORM can offer the following:

- Materials including (but not limited to) HMW-HDPE, LDPE, ABS, TPE, PE-100

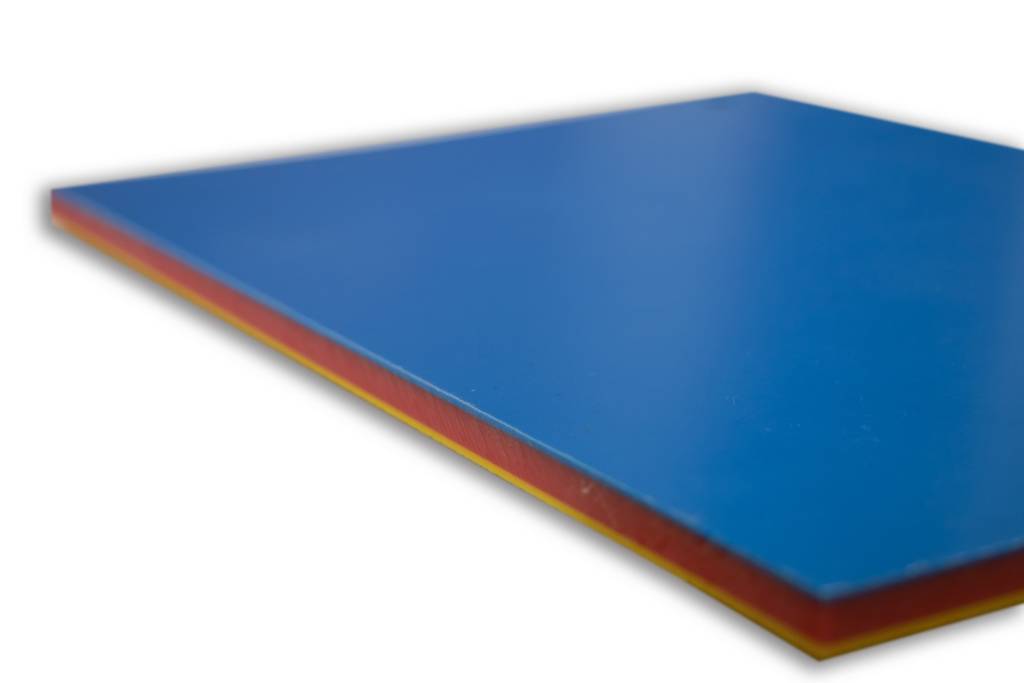

- Multi-layer extrusion A/B – A/B/A – A/B/C with multiple colours or materials

- Smooth, Levant or Haircell finish options

- Colour to match any Pantone code

- Material additives including UV resistance, chemical resistance and flame retardant

- Virgin, regrind or a blended material masterbatch options

- Custom sheet sizing available

- Sheet or roll packaging

- An output of up to 1300kg of sheet per hour

- ISO 9001 certified

Common Plastic Sheet Extrusion Applications

| Agriculture/Equine Troughs Tanks Cladding Fence Cladding Feeder Bins |

| Automotive Ute Liners Boot Mats Spacers Ute Lids Ute Canopy Shells |

| Industrial Cladding Pallets Conveyors CNC Parts |

| Recreational / Other Pools Kayaks Boats Playgrounds Signage Portable Toilets Scaffolding POS Displays |

Extrudable Materials

PRO-FORM run a range of different material masterbatch in their plastic extruders. Each material has different chemical and physical properties which are best suited to different applications. To learn more about what materials might be best for your application, get in touch with one of PRO-FORM’s knowledgeable sales staff.

- High-Density Polyethylene (HDPE)

- Thermoplastic Elastomer (TPE)

- Acrylonitrile Butadiene Styrene (ABS) / (AES)

- Polypropylene (PP)

- Polyethylene 100 (PE-100)

- Other materials or blends on request – speak to our staff if you require a different material to be run

Recycling

- PRO-FORM practice lean manufacturing and re-use plastic off-cuts in internal applications

- It is recommended that any external plastic off-cuts are supplied back to PRO-FORM to be recycled

- PRO-FORM are actively seeking new opportunities to use recycled materials. If you know of any potential recycling products or projects then please get in touch, they’d love to talk.

If you would like a quote or to learn more about PRO-FORM’s plastic extrusion capabilities then get in contact with their team to find out more.